A plenum is a big part of an HVAC system, but what is the purpose of a plenum? Simply put, it distributes and collects air. It’s the central hub of air flow in a building. This article will cover the types of plenums, their functions and the importance of installation and maintenance.

Key Points

- Plenums, as a crucial part of the HVAC system, play a significant role in maintaining indoor comfort and air quality by facilitating cool or warm air distribution, mainly supply and return.

- Proper installation and maintenance of plenums are crucial for efficiency, code compliance, and preventing energy loss and safety hazards.

- Common issues with HVAC plenums, such as leaks and dirt accumulation, can lead to poor air quality and high energy bills, so regular inspections and timely repairs are a must.

What Are Plenum Boxes in HVAC Systems?

The plenum is the heart of your HVAC system, it’s the central hub of air flow. It ensures conditioned air reaches every corner of the building effectively, providing consistent temperatures and comfort throughout. But what is a plenum, and why is it so important?

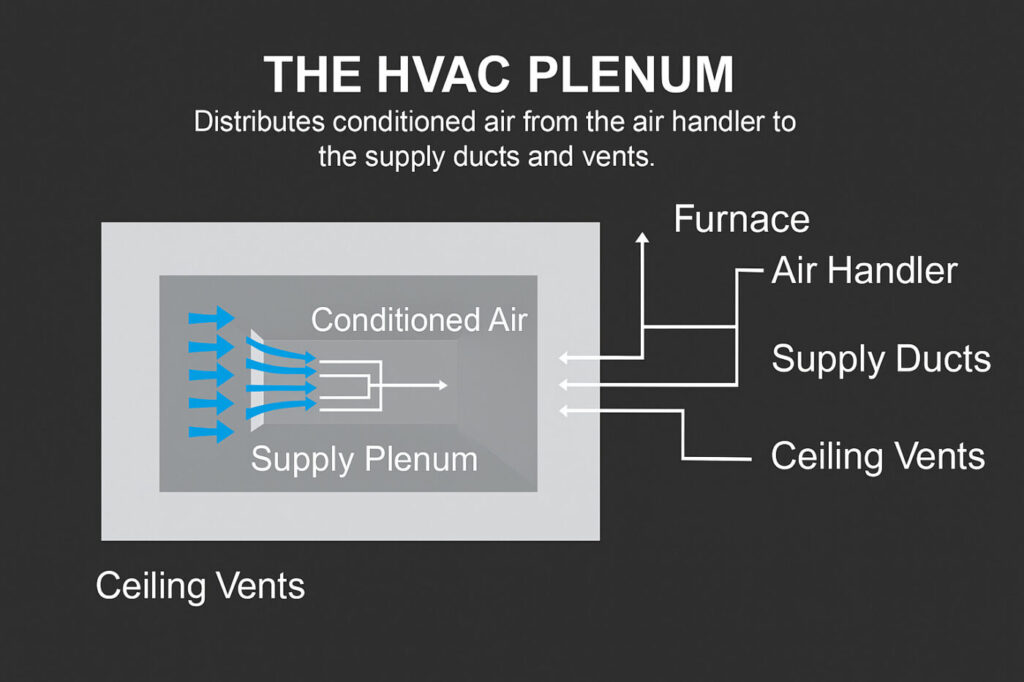

HVAC plenums can be categorized into:

- Supply plenums: Distribute conditioned air from the air handling unit to different parts of the building.

- Return plenums: Collects the used air and sends it back for reconditioning.

- Transition plenums

- Auxiliary plenums

Balanced airflow is key to the system’s efficiency and indoor air quality with air conditioning.

Proper installation of HVAC plenums is not just about comfort – it’s also about safety. Code compliance is key to fire safety and overall system efficiency. Poorly installed plenums can lead to energy losses and even fire hazards, so code compliance is a must.

Typically, two plenums are needed for a central HVAC system to work correctly: a supply plenum and a return plenum. These two plenums work together to create balanced airflow and make your HVAC system efficient.

Supply Plenums: Distributing Conditioned Air

The supply plenum is connected to the air handling unit, which facilitates the flow of treated air into the ducts. This connection is crucial as it ensures the cool or warm air generated by your HVAC system is distributed throughout the building. A well-designed supply plenum facilitates even air distribution, thereby reducing the workload of the HVAC system and leading to energy savings. A properly installed supply plenum maintains consistent temperatures across different rooms.

So next time you enjoy a perfectly cooled or heated room, remember the unsung hero – the supply plenum – working behind the scenes.

Return Plenums: Collecting Air for Reconditioning

While the supply plenum distributes conditioned air, the return plenum plays a vital role:

- It collects air from inside the building.

- It sends the collected air back to the air conditioner or furnace for reconditioning.

- This creates a negative pressure zone.

- The negative pressure pulls unconditioned air into the ductwork.

- The unconditioned air is then treated and redistributed as needed.

The return plenum ensures the air in your building is continuously cycled and conditioned, maintaining a comfortable and healthy indoor environment. Without a functioning return plenum, your HVAC system would struggle to maintain airflow and temperature control, resulting in poor indoor air quality and high energy bills.

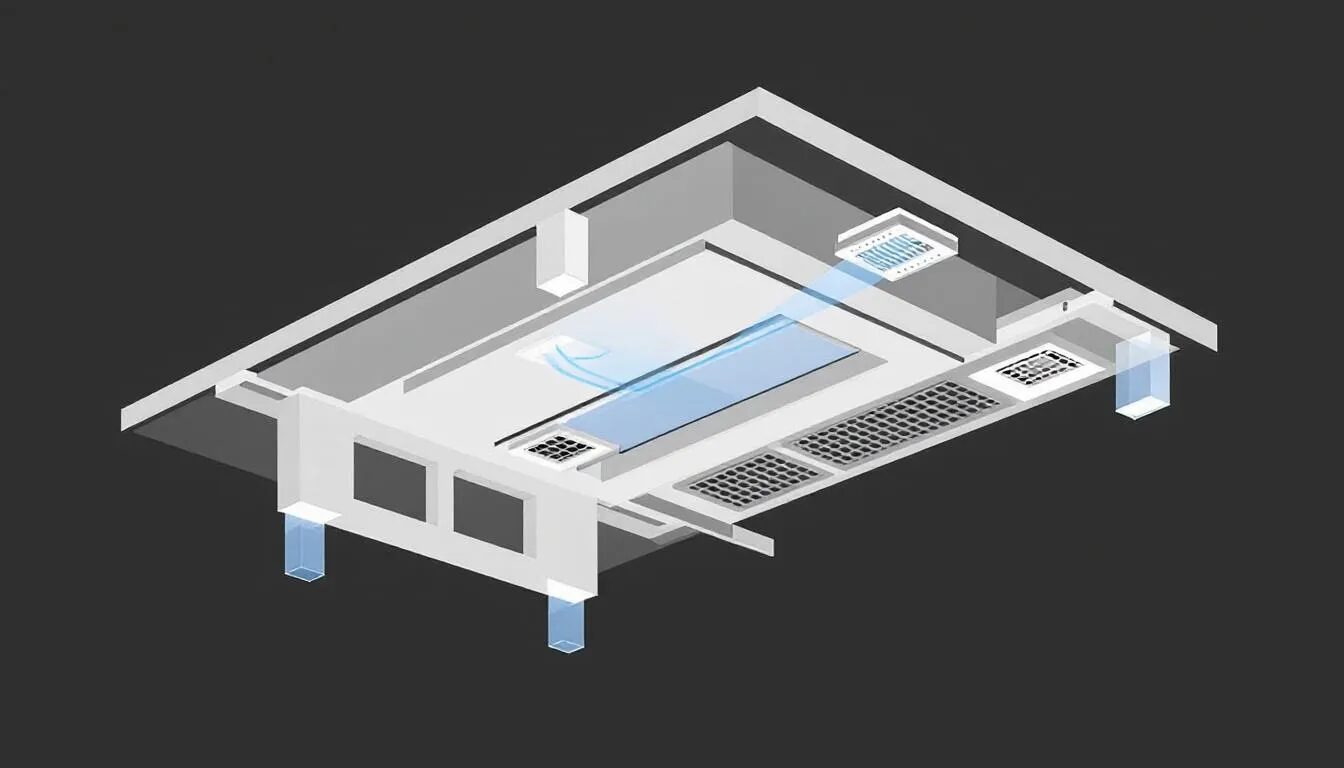

Plenum boxes may vary in shape and size

HVAC plenum boxes come in different shapes and sizes, each designed to meet specific needs. These components are made of sheet metal and connect the air handler to the ductwork. Knowing the different types of plenums is key to efficient cool or warm air distribution and overall system performance.

The main types of plenums are supply and return, but they can also be classified based on design, shape, size, and location.

Knowing the different types of HVAC plenums helps in selecting the right one for your system, for optimal performance and energy efficiency. Whether it’s a standard rectangular plenum or a custom-sized one, each type has its advantages and applications.

Rectangular Plenums

Most HVAC plenums are box-shaped, allowing for efficient airflow management. These rectangular plenum boxes and two plenum boxes are designed to fit within the structural ceiling or floor space, making them a popular choice for many HVAC systems. Their shape and design allow smooth air circulation, so conditioned air is distributed evenly throughout the building.

Custom-Sized Plenum Boxes

Custom-sized plenums are designed to fit the unique requirements of different HVAC systems. These plenums can be fabricated from sheet metal to match the exact dimensions needed for optimal airflow and efficiency.

Customization is especially useful for buildings with unique architectural constraints or specific airflow material requirements.

Importance of Proper Plenum Installation

Proper plenum installation is key to optimal airflow, code compliance and energy loss. The effectiveness of cool or warm air distribution and the overall energy efficiency of an HVAC system are dependent on how well the plenums are installed. Common issues with HVAC plenums, such as leaks, can lead to significant energy losses and reduced system performance.

Improper installation of plenums can drastically decline the overall performance of HVAC systems. Issues like leaks, poorly sized plenums and improper connections can hinder airflow and make the system work harder and consume more energy. Ensuring the correct installation of plenums is crucial for maintaining the efficiency and longevity of your HVAC system.

Following building codes and standards during plenum space installation ensures safety and compliance. This not only helps in achieving optimal performance but also prevents potential legal liabilities and promotes safety in both residential and commercial buildings.

Energy Efficiency and Airflow

Proper plenum installation minimizes energy consumption by optimizing airflow and reducing the load on HVAC systems. By minimizing air resistance, turbulence and noise, correct plenum installation improves overall HVAC efficiency. Plenums that are not appropriately sized can create uneven airflow and add extra strain to HVAC systems.

Custom-sized plenums can be fabricated to match the specific dimensions required by unique HVAC installations. Regular maintenance of HVAC plenums can improve system efficiency and extend their life.

Remember! Maintenance of your HVAC plenum can improve air quality and system efficiency.

Code Compliance

Following building codes during plenum installation is crucial for safety standards, especially for fire protection. Meeting building codes for plenum installation ensures fire safety and proper ventilation as per regulations.

Following national standards during plenum cabling installation prevents legal liabilities and promotes safety in residential and commercial buildings, as per the National Fire Protection Association. This is a test for compliance with safety regulations.

Common Issues with HVAC Plenums

Common issues with HVAC plenums can impact the system’s overall performance and energy efficiency. From leaks to dirt accumulation and incorrectly sized plenums, these problems can cause uneven temperature distribution, high energy bills and poor indoor air quality. Addressing these issues is key to maintaining HVAC efficiency and indoor comfort. Poor indoor air quality can result from a faulty plenum due to dust and allergen circulation. This affects comfort and can be a health risk, so it’s essential to check and maintain your HVAC plenums regularly. Signs of plenum replacement include uneven temperature in rooms and high energy bills.

Knowing these common issues can help you take proactive measures to ensure your HVAC system runs smoothly.

Regular inspections and timely repairs can prevent minor problems from becoming major issues.

Plenum Leaks

Plenum leaks waste energy, hinder temperature control and make the HVAC system work harder. To identify and repair a plenum leak:

- Check the airflow from the plenums near the air handler.

- Do a visual inspection to help detect leaks.

- Repair a plenum leak with silicone caulk and aluminum tape.

These leaks can cause huge energy loss and uneven temperature distribution across different rooms. Addressing leaks ASAP is crucial to maintain the efficiency and performance of your heating HVAC system.

Regular inspections and maintenance can help you identify and fix leaks before they become major issues.

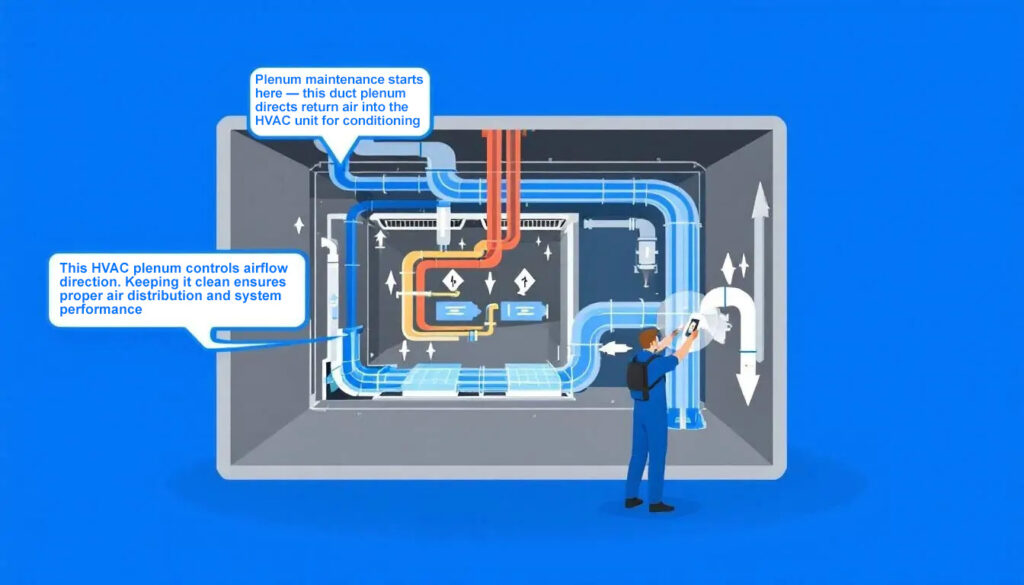

Dirty Plenums

Dirt accumulation in plenums can block airflow and deteriorate indoor air quality. Cleaning plenums regularly enhances airflow and indoor air quality. Air filters in the supply plenum should be cleaned or replaced every few months to prevent dirt accumulation. Changing air filters regularly prevents airflow obstruction caused by dirt and debris.

To ensure effective airflow and indoor air quality:

- Have professional air duct and plenum cleaning every 3-5 years.

- Engage a professional to clean plenums to maintain efficiency and prevent microbial growth and air pollution.

- Regular cleaning ensures your HVAC system runs efficiently and maintains a healthy indoor environment.

Incorrectly Sized Plenums

Improperly sized plenums can cause various issues in HVAC systems, significantly affecting their efficiency and performance. Incorrect plenum sizing can cause uneven airflow, leading to temperature distribution and high energy bills.

Proper installation and correct plenum sizing are crucial for efficient airflow and reducing the overall load on HVAC systems.

Plenum Maintenance

Maintaining your plenum ensures your HVAC system runs smoothly. Dust or dirt can accumulate in plenums, making them inefficient. Regular maintenance, including changing air filters and professional cleaning, can help maintain optimal airflow and indoor air quality. Return plenums connect to air filters, which clean the air before it goes back to the return ducts of the HVAC system for reconditioning. This is important for a clean and efficient HVAC system.

Regular maintenance not only improves system performance but also extends the life of your equipment.

Filter Changes

Filters should be changed every 3 months to keep plenums clean. Regular maintenance ensures the efficiency and longevity of HVAC systems. Filters prevent dirt buildup in plenums.

Consistent filter changes make a significant difference in the overall performance and air quality of HVAC systems.

Professional Cleaning

Professional air ducts cleaning is recommended every 3-5 years for plenum maintenance. Periodic professional cleaning of HVAC systems maintains optimal airflow and indoor air quality.

Regular professional cleaning ensures unobstructed airflow and removes contaminants, improving overall air quality in the building. A clean HVAC system through professional cleaning enhances energy efficiency and extends equipment life.

Repairing or Replacing Plenums

Plenums should be cleaned, repaired or replaced when there’s an issue with its function. The cost for a new plenum installation is around $100 to $200. You can expect to pay HVAC professionals an hourly rate of $50 to $150 during plenum installation. The process of replacing a plenum involves:

- Inspection

- Removal of the old unit

- Fabrication of a new one (if necessary)

- Installation

- Testing of the system

A typical plenum installation takes a few hours at most.

While DIY plenum replacement is possible, it’s recommended to hire a professional technician because:

- They have the expertise to install plenums correctly.

- They have the necessary tools for installation.

- Proper installation ensures optimal performance of your HVAC system.

- It avoids complications and extends the life of your system.

Conclusion

In summary, plenums are crucial to the operation of HVAC systems. They ensure conditioned air is distributed throughout the building and unconditioned air is collected for reconditioning. Understanding the types of plenums, their role, and the importance of proper installation and maintenance can help you keep your HVAC system running smoothly. Regular maintenance, including filter changes and professional cleaning, is necessary for optimal airflow and indoor air quality. Fixing common issues like leaks, dirt buildup and improperly sized plenums can greatly improve your HVAC system’s efficiency and lifespan. By paying attention to these details, you can have a comfortable and healthy indoor environment.

FAQs

A supply plenum is used to distribute conditioned air from the air handling unit to the building. This ensures optimal airflow and temperature control in the indoor environment.

Plenums should be cleaned professionally every 3 to 5 years for optimal performance and air quality. Regular maintenance at these intervals can prevent issues and improve system efficiency.

You can replace a plenum yourself, but it’s recommended to hire a professional to ensure proper installation and avoid problems.

Replacing a plenum costs around $100 to $200, not including labor. So it’s best to budget for additional installation costs.

Signs of a bad plenum are uneven temperatures in your space, high energy bills and poor indoor air quality. Fixing these issues ASAP can improve comfort and efficiency.